How FDM Printing is Revolutionizing Architecture and Design

FDM Printing in Architecture, Design, and Traditional Engineering: Dynamism & Ultimaker Shine at Dubai Design Week

Karolina Moskal

Karolina.m@dynamism3D.com

Dubai Design Week, the Middle East’s premier design event, served as the global stage for Mitsubishi Estate’s visionary 3D-printed teahouse. This groundbreaking creation seamlessly merged traditional Japanese culture and heritage with FDM 3D printing technology, offering a captivating showcase of architectural innovation. Dynamism played a key role in supporting the 3D printing of teahouse components, which were all done using a wood-based filame

nt. These parts were then shipped to Dubai, where they were seamlessly assembled into the stunning final structure.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250116842687/en/

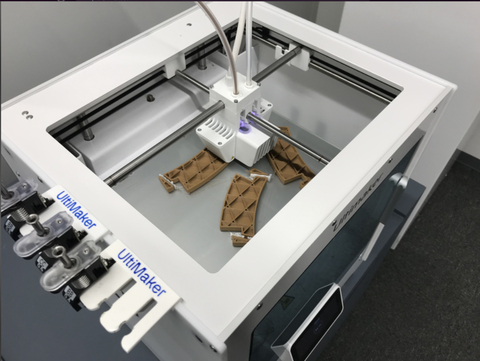

;">1,938 meticulously crafted “hozo” joints are printed on Ultimaker S series printers completing approximately 4,000 hours of printing to bring the project to life. (Photo: Business Wire)

Dubai Design Week: A Global Hub for Creativity

Dubai Design Week is renowned for uniting designers from around the world to inspire creativity and foster innovation. The annual event features exhibitions, pop-ups, installations, and talks that engage professionals, media, and design enthusiasts while strengthening Dubai’s reputation as a vibrant design capital.

The 3D-Printed Teahouse: Tradition Meets Innovation

The 3D-printed teahouse stood out as a beacon of innovation at Dubai Design Week. By merging traditional architecture with modern 3D printing, this ambitious project showcased how additive manufacturing can preserve cultural heritage while pushing the boundaries of design and engineering.

Traditional Japanese Engineering Influences

The teahouse design drew heavily from Japanese traditions, particularly the “hozo tsugi” joinery technique. This ancient method involves interlocking wooden joints without nails or screws, a skill-intensive practice that ensures durability and elegance. To recreate this authentically, Polywood—a wood-infused resin filament—was used to replicate the aesthetic of traditional Japanese tea rooms.

Ultimaker’s Role in Precision Printing

Key to the project’s success was Ultimaker’s S series 3D printers. Using digital renderings, the intricate teahouse design was divided into 988 individual parts, including 1,938 meticulously crafted “hozo” joints. The Ultimaker printers delivered unparalleled precision, completing approximately 4,000 hours of printing to bring the project to life. The printers’ versatility enabled the seamless integration of traditional engineering with advanced FDM printing techniques.

The Significance of the 3D-Printed Teahouse

The teahouse was more than an architectural marvel—it symbolized the harmonious blending of tradition and technology. Leveraging FDM printing, this demonstrated the transformative potential of additive manufacturing to preserve and reimagine cultural heritage. The teahouse captivated a global audience, underscoring the possibilities of 3D printing in architecture, design, and engineering.

Bridging Heritage and Innovation

Dynamism’s contribution to Dubai Design Week highlighted the growing role of 3D printing in modern design. Projects like the 3D-printed teahouse not only showcase the technological capabilities of FDM printing but also emphasize its power to honor and elevate tradition. As a leader in advanced 3D printing solutions, Dynamism continues to inspire by merging the past with the future through innovative designs.

View source version on businesswire.com: https://www.businesswire.com/news/home/20250116842687/en/

Business wire

Business wire

Add Comment